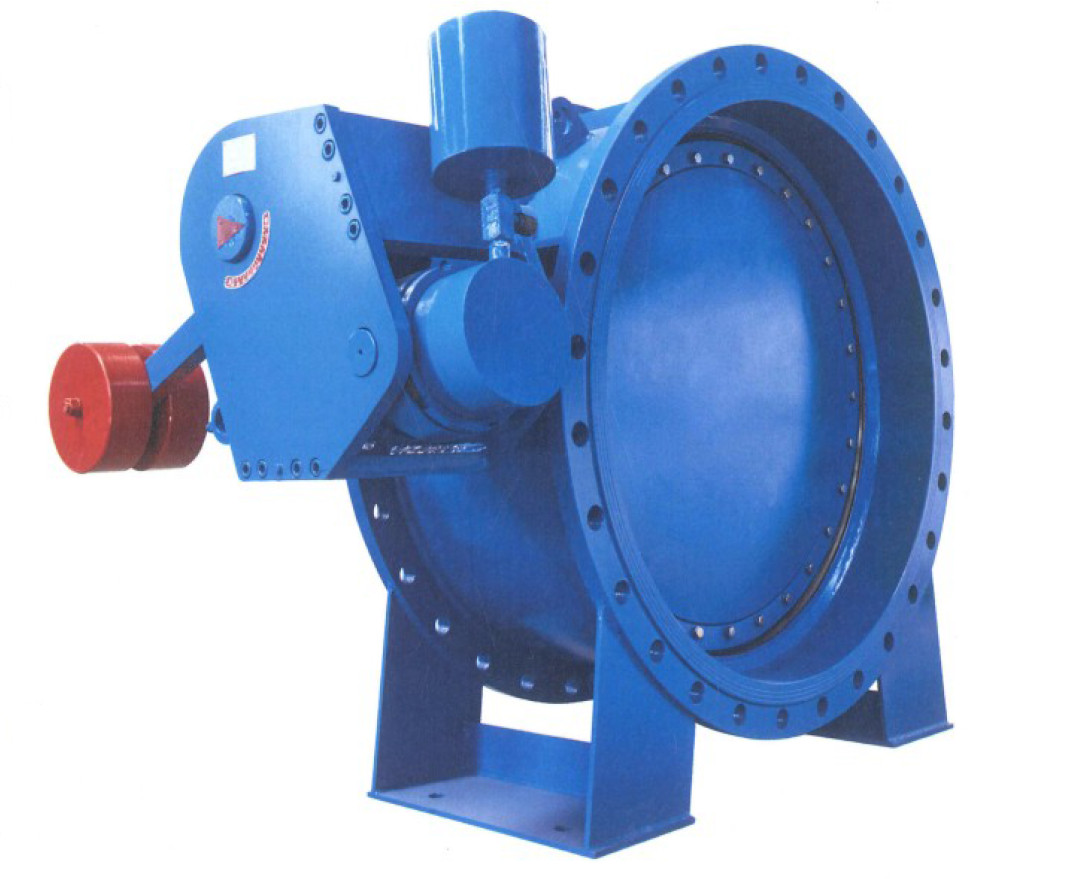

Micro Resistance Slow Ukuvala Hlola iiValves

Iimbonakalo

▪ Ixesha elinokutshintshwa.

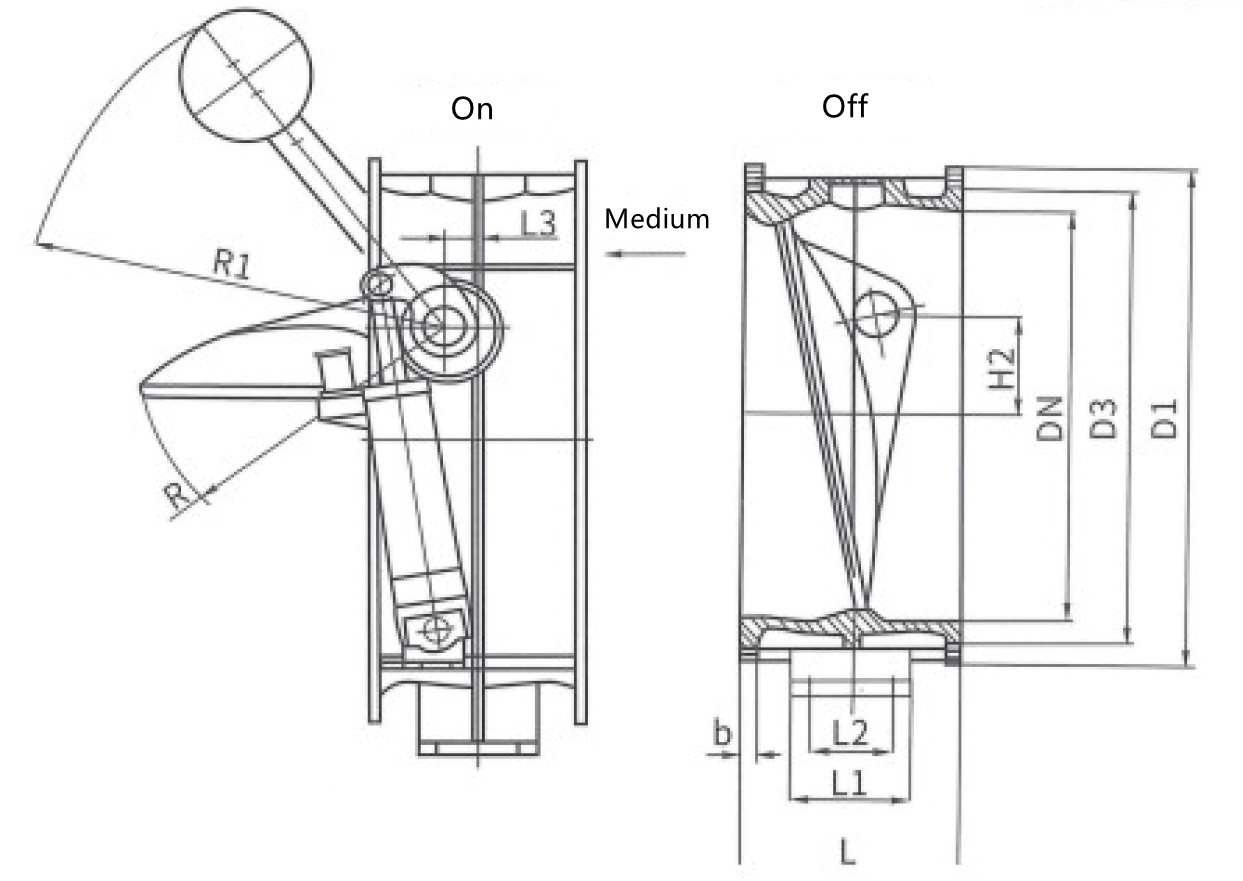

▪ Imo yokuvala ivalvu: vala ngokukhawuleza nangokucothayo.

▪ Ulwakhiwo oluphindwe kabini Idiskhi, ukuvuleka kwevalvu okufanelekileyo kunye nentshukumo yokuvala.

▪ Zonke iperi etywiniweyo etywiniweyo kunye neperisi ekwaziyo ukumelana nerabha, kunye nenkonzo yexesha elide, ukugcinwa simahla kunye nokutshintshwa simahla.

▪ Kumaqalela olwakhiwo lwevalvu yendawo enxulumene neempawu zokuxhathisa ukuhamba, izinto zejometri zimiselwa ngokusebenzisa umgaqo we-hydrodynamics ukunciphisa ukuxhathisa kokuhamba kunye nokugcina amandla.

▪ Ukusebenza kakuhle kwevalve kuthintela ukwenzeka kwehamile yamanzi eyonakalisayo.

▪ Idiskhi / isiqu sevalve sinokuvulwa kwaye ivalwe ngokuthambileyo ngaphandle kokuxinana.

▪ Ukukhethwa kunye nokumataniswa kwezinto ezimbini zokukhuhlana, uyilo lwesakhiwo sokutywina kunye nokulungelelaniswa kofakelo kunokuqinisekisa ukuba iindawo ezijikelezayo ezifana nediski / i-valve stem inokugcina ukusebenza kakuhle kokujikeleza ixesha elide.

▪ Ubulula, ukuchaneka kunye nokhuseleko lomsebenzisi kunye nokugcina ukusebenza kakuhle kwemveliso.

▪ Ubude besakhiwo esifutshane kunye nobunzima obulula.

▪ Uvavanyo loxinzelelo:

Uxinzelelo lovavanyo lweShell 1.5 x PN

Uxinzelelo loVavanyo lweSitywina 1.1 x PN

Iinkcukacha zezinto eziphathekayo

| Inxalenye | Izinto eziphathekayo |

| Umzimba | Intsimbi yekhabhoni, isinyithi se-ductile |

| Icwecwe | WCB |

| Isiqu | 2Kr13 |

| Umsesane wokutywina | Buna-N, EPDM, FKM |

| Isilinda Piston Ring | I-alloy cast iron |

| Ezinye izinto ezifunekayo zingaxoxwa. |

Ulwakhiwo

Isicelo

▪ Le valve yokutshekisha luhlobo olutsha lwemveliso egcina umbane yehamile engangeni manzi enesihlalo sevalve esithe nkqo okanye esithe tye, idiskhi ye-double offset, zonke iperi yentsimbi etywinayo kunye nepeyi yokutywina yerabha engagugiyo, into ephuphumayo enolwelo lomjelo kunye noxinzelelo lweoyile isixhobo sokuvala ngokucothayo, enokuvala ivalve ngezigaba ezikhawulezayo / ezicothayo.

▪ Ivalve inokonga amandla ngokucacileyo xa isebenza.Xa impompo iqhelekile okanye ipompo imisiwe kwimeko yokungaphumeleli kwamandla ngequbuliso, inokuthintela ngokufanelekileyo ukubuyela umva komzimba wamanzi kunye nokuvela kwehamile yamanzi eyonakalisayo.

▪ Isetyenziswa kakhulu kwi-petrochemical, i-metallurgy yamandla, unikezelo lwamanzi asezidolophini kunye ne-drainage kunye nezinye iinkqubo zemibhobho.